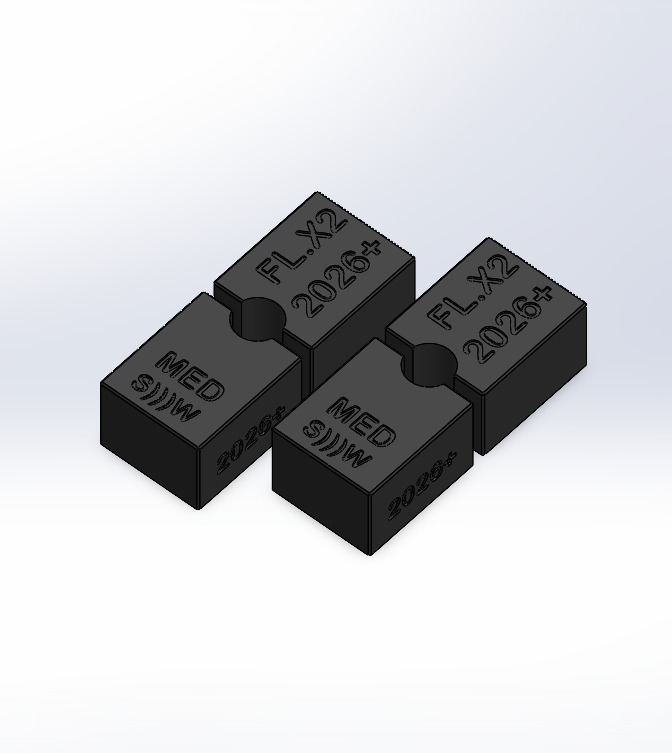

Shockwave Parts

Float X2 2026+ Small Shaft Clamp (1/2")

Float X2 2026+ Small Shaft Clamp (1/2")

Couldn't load pickup availability

⚠️ Important Warning – Read Before Buying

This tool is very easy to misuse. You must read our clamp manual or you will probably break it.

Each purchase includes two clamps (a pair). If you break one by skipping the guide, you still have a backup. If you follow instructions, both will likely last indefinitely.

Buying all three stroke sizes? You’ll receive six clamps total (2 per length). These are printed in-house and take time to produce. Please treat them carefully.

Click here to read the usage manual before buying »Float X2 2026+ Small Shaft Clamp (Experimental)

This is our early prototype shaft clamp for the new 2026+ Float X2 shocks. It’s based on visual analysis and supplier info so far, the clamp fits a 1/2" shaft, but the width and fitment are still experimental until we get all stroke lengths in hand. If you’re ordering this early, you're helping us confirm real-world compatibility.

What It Does

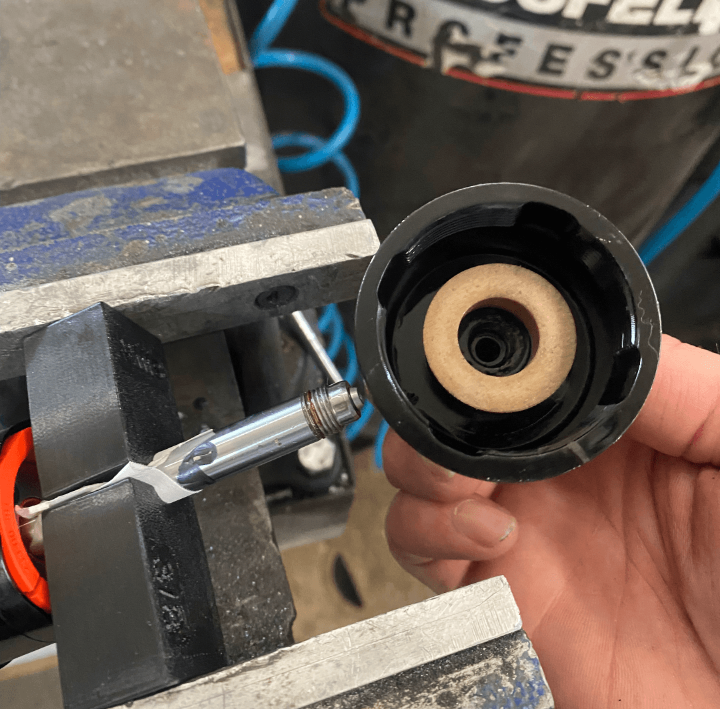

This clamp is designed to let you securely hold the damper shaft in a vise during service, especially for removing or reinstalling the eyelet. As with previous models, it wraps around the shaft and grips it using internal ribs and friction.

- Designed for Float X2 2026+ 1/2" damper shafts

- Confirmed stroke ranges and clearance still pending, we’ll update as we test

- ❌ Not compatible with 2016–2025 Float X2 shocks

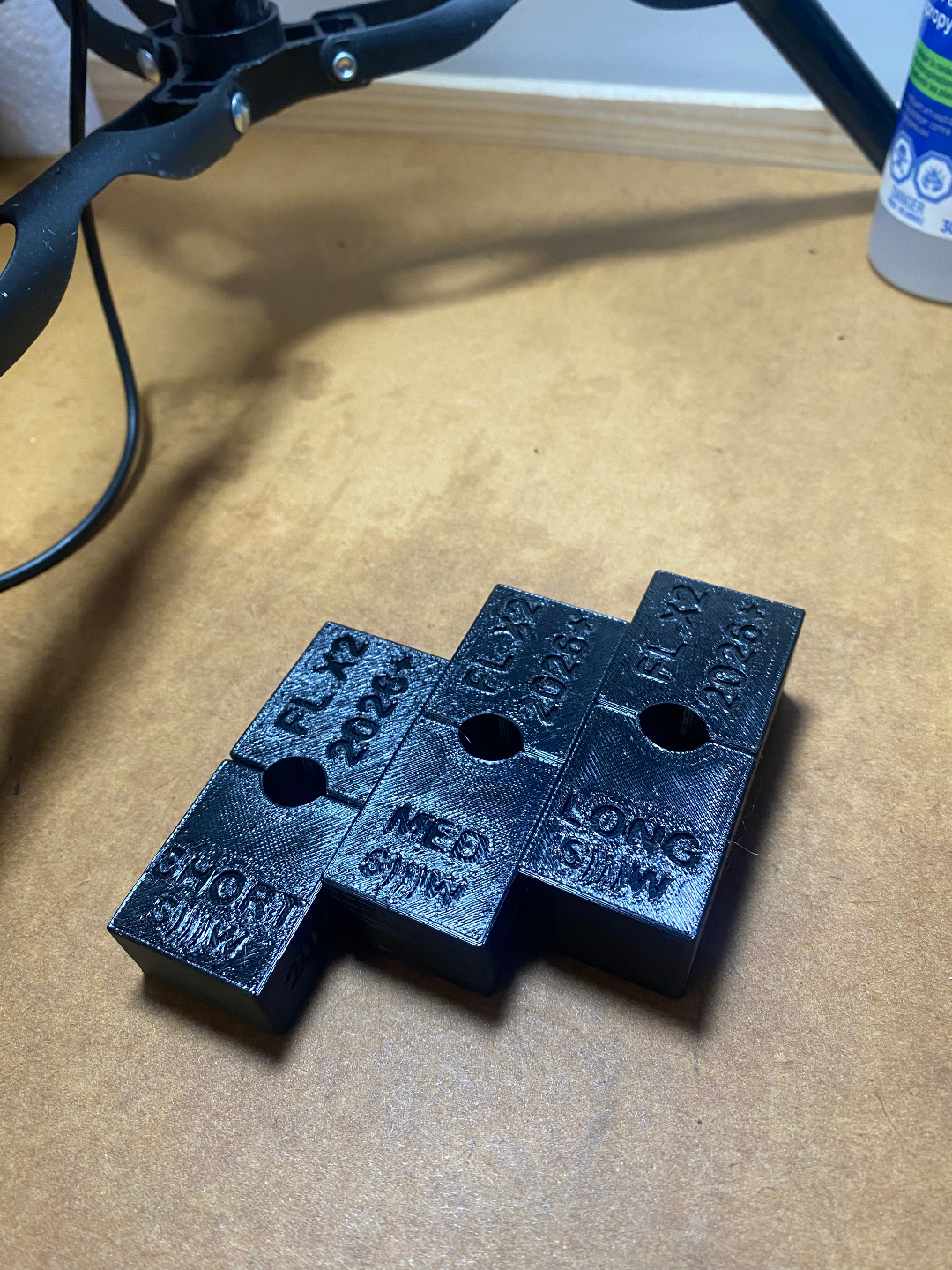

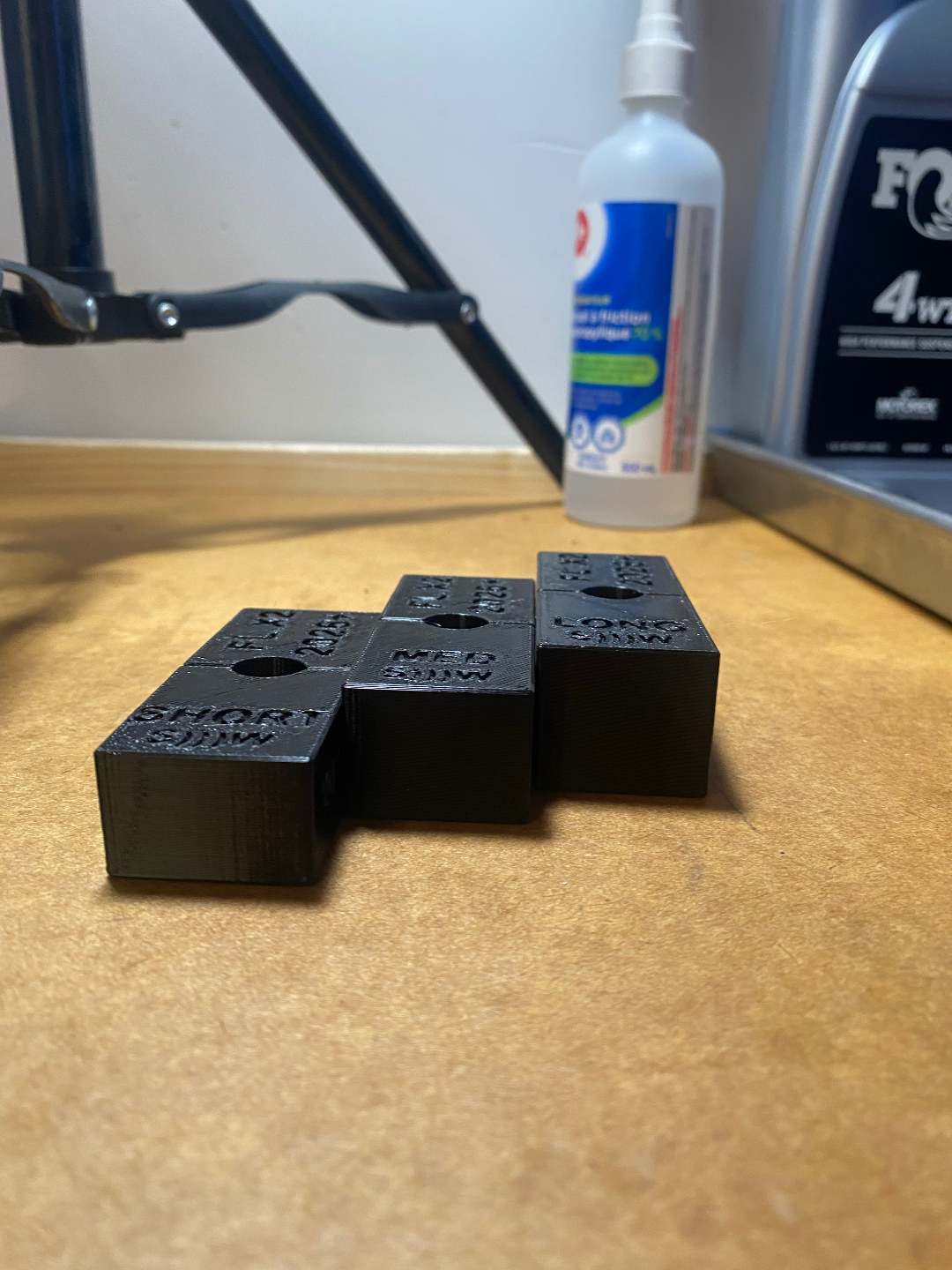

Which Height to Choose?

- Short: Likely for 52.5–57.5 mm strokes (to be confirmed)

- Medium: Likely for 60–62.5 mm strokes

- Long: Likely for 65–75 mm strokes (worst option if uncertai, 0.5inch is quite big so the shorter clamp will likely work for all the strokes)

Tip: We recommend choosing the short version if you’re not sure what stroke you have. It will likely cover all lengths as long as your air can is screwed all the way down into the negative sealhead.

As of now, use this only if you’re comfortable helping validate the fitment, we’ll post updates and refine the design if necessary.

How to Use

- Clean the shaft completely with isopropyl alcohol

- Wrap with dry paper towel to prevent slipping

- Clamp evenly in a vise, do not overtighten

- Use heat (heat gun or torch) on the eyelet : Fox uses red Loctite

Read the Full Small Shaft Clamp Manual : follow this exactly or the clamp will break.

Disclaimer

⚠️ Use at your own risk. By purchasing, you agree to our terms of service.

Share