Shockwave Parts

RockShox Charger 3/3.1 Damper Rebuild Tool

RockShox Charger 3/3.1 Damper Rebuild Tool

Couldn't load pickup availability

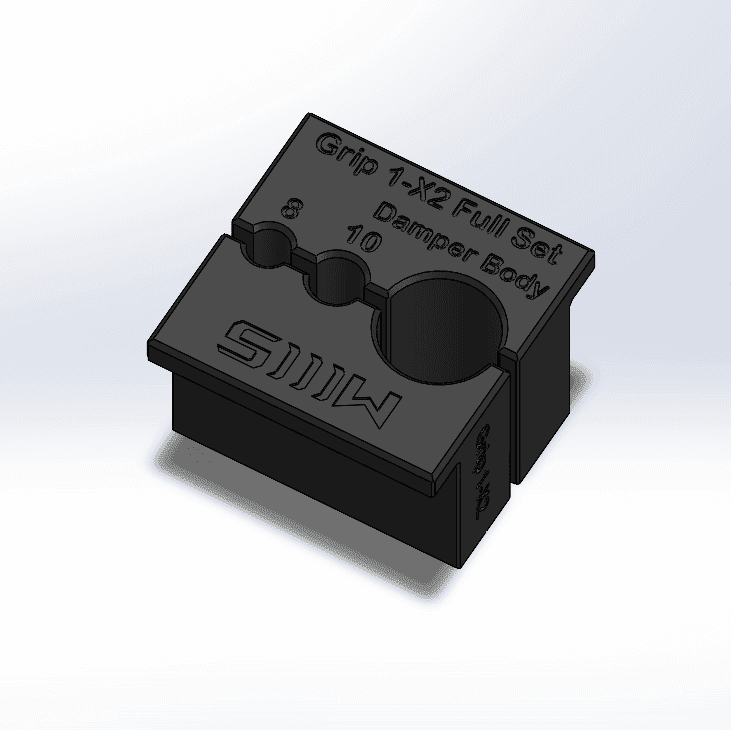

RockShox Charger 3 & 3.1 Damper-Only DIY Rebuild Toolkit

All the tools you need to fully open the RockShox Charger 3 or 3.1 damper cartridge, designed for people who already have the lower-leg and air-spring tools. This is for the damper only.

ZEB, Lyrik, and Pike Ultimate / Select+ (2023+) all use one of these dampers.

Need Seals?

Included & Recommended Extras

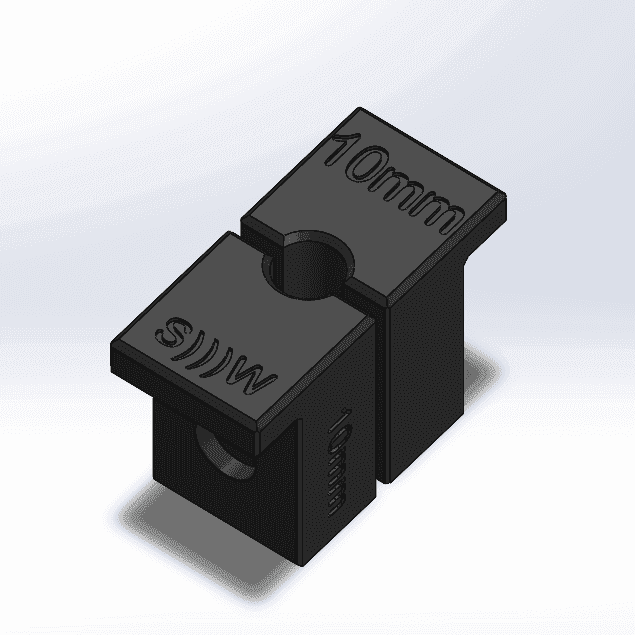

- 10 mm Shaft Clamp, fits the main Charger 3 / 3.1 damper shaft

Highly Recommended Extras:

- 10" Knipex Pliers: the best tool you can buy for fork/shock work

- Park Tool Cassette Tool: required for removing the damper top cap

Also needed: SRAM Butter and RockShox 4wt (varies by model).

Essential Tools Starter Pack: all general suspension tools

MTB Suspension Jargon for Beginners: if this is your first damper rebuild

How to Bleed & Rebuild (Read Carefully)

- The only difference between Charger 3 and 3.1 is the base-valve piston.

SRAM Service Manual (PDF): Pages 134–138

Excellent explanation of bleed technique and failure symptoms: Watch from 14:50

Charger 3 vs 3.1 base-valve comparison: Read here

Disclaimer

⚠ Only the 10 mm shaft clamp is included in this listing. Proceed at your own risk. Refer to official SRAM documentation for full procedures.

See our Terms of Service.

Share