Shockwave Parts

FOX FLOAT X CTD (2014–2017) DIY Tools kit

FOX FLOAT X CTD (2014–2017) DIY Tools kit

Couldn't load pickup availability

FOX FLOAT X CTD (2014–2017) Rebuild Manual

The FLOAT X CTD (2014–2017) shares many similarities with the DPX2 internally. The rebuild flow is nearly the same.

Reference Procedures (Required Reading)

- DPX2 rebuild procedure (hand-bleed method shown): FOX DPX2 Rebuild

- Official FLOAT X CTD manual: FOX 2014–2017 FLOAT X Rebuild

Note: If the FOX manual doesn’t show a hand-bleed method, use the DPX2 flow for that portion.

General Notes

- Most compression/lockout problems come from oil volume, IFP pressure, or air trapped in the damper

- Proper rebuild fixes most issues, don’t open adjusters unless necessary

Tools Included in Our Kit

- 1/2″ Shaft Clamp — fits the main shaft on this shock

- Graduated IFP Depth Tool — required for setting correct IFP depth

- High-Torque Metal Pellet Retainer Tool — required; plastic versions do not work reliably

What You Must Buy (Not Included)

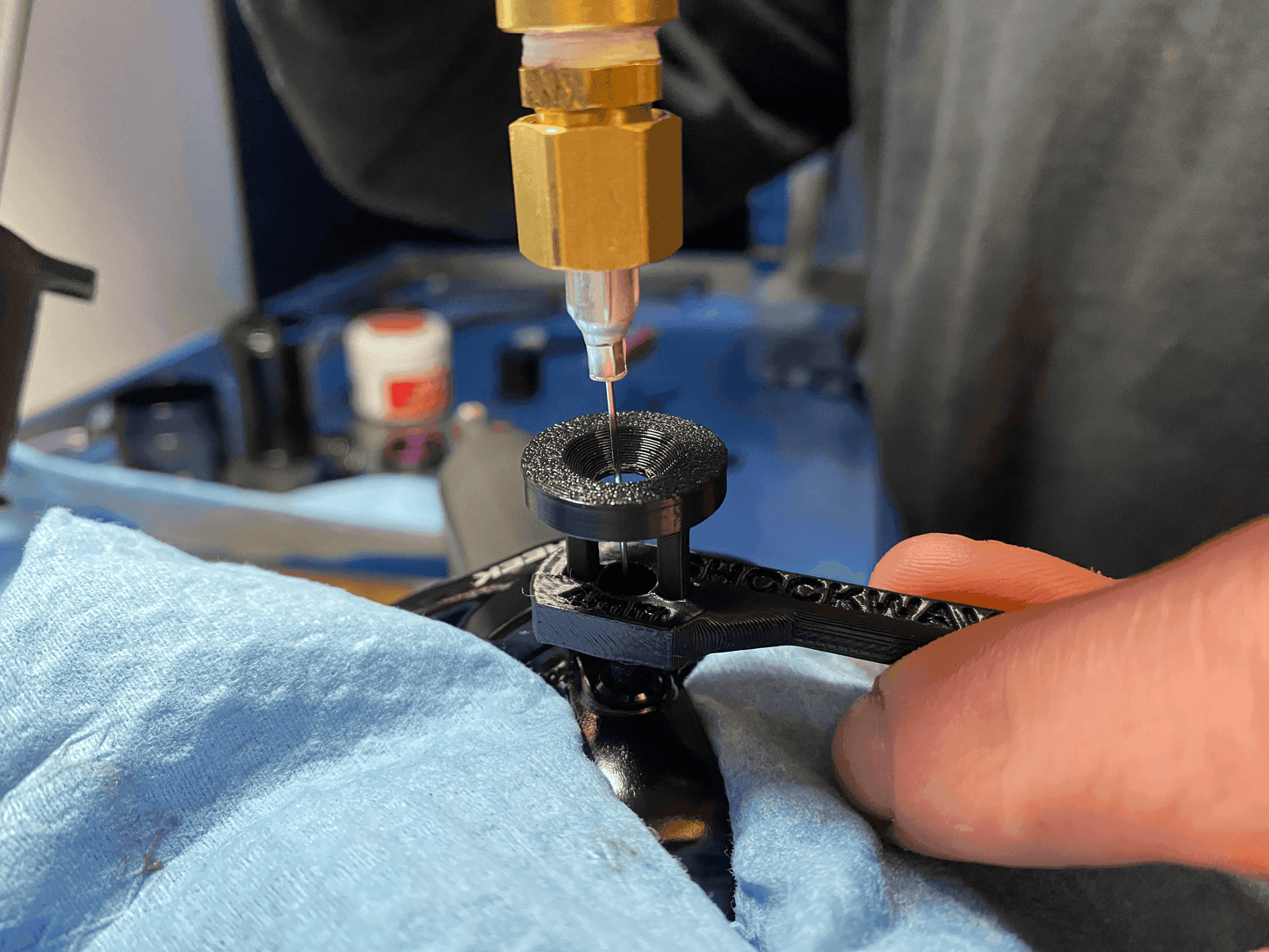

- Needle-Style IFP Fill Adapter required (this shock does not use a Schrader valve)

If you don’t have a needle fill adapter, you will not be able to safely release or refill damper pressure, don’t start without it.

Pellet Retainer Tip

This shock requires a pellet retainer tool for needle-style IFP pressurization.

You can make one yourself with a Dremel and a 4 mm Allen key.

Important: This model specifically needs a strong metal retainer; weak plastic ones often fail.

Specs

- IFP Depth: 1.35″

- IFP Pressure: 150 psi

- Damper Oil: Original FOX 10wt Red (discontinued); use any modern 10wt (e.g., 10wt Green)

Safety Notes

- Release air spring pressure before opening the air can

- If it sucks down because you released too fast: reinflate, then drop in ~25 psi steps and equalize the chambers each time

- Then release damper / IFP pressure using the correct needle fill adapter

- Never open a bleed screw or damper body while pressurized

Disclaimer

These procedures are intended for experienced home mechanics only.

Improper handling of pressurized suspension components can cause serious injury or equipment damage.

By continuing, you agree to our Terms of Service and assume full responsibility.

Share